Products

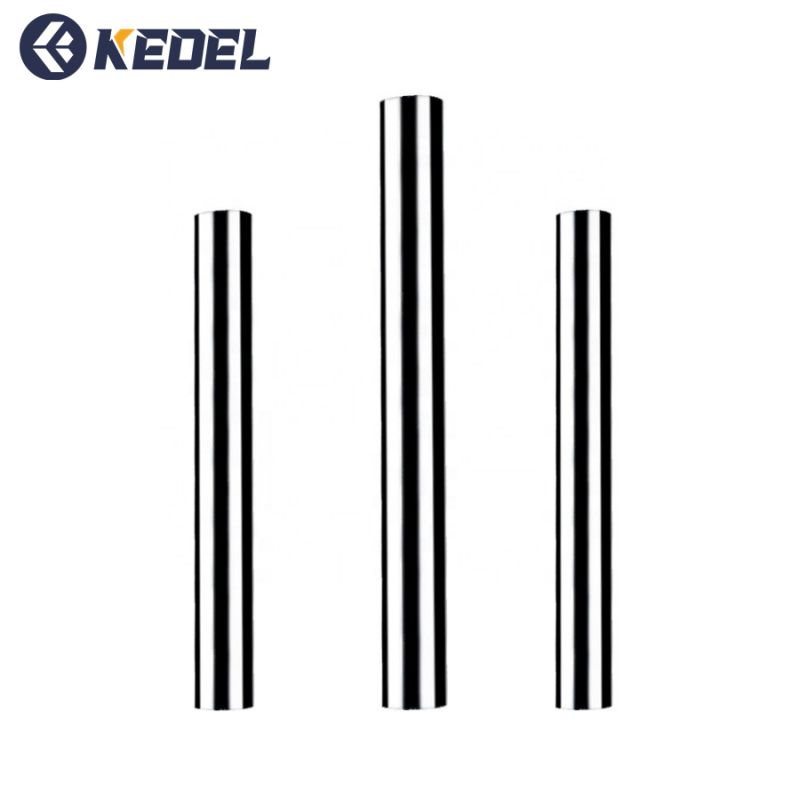

Solidum Wolframium Carbide Rods

Carbide dii Descriptio

Tungsten carbida late adhibentur ad premium solidorum instrumentorum carbidum faciendi, ut molendina, terebras, reamers, serratores molendi, terunt, instrumenta metiendi in diversis industriis. Instrumentum artificiorum in summo artificio Kedel et carbide qualitate consistens in variis gradibus in quibus K20F, K25F , etc. Baculos carbidos et solos et tritos suppeditamus.Modus comprehensus delectu virgarum carbidum tungsten in variis dimensionibus in promptu est, et nos quoque officia customizationes iuxta exigentias tuas offerimus.Ut ISO fabrica, Kedeltool utuntur materiae qualitati summo, ad qualitatem et observantiam virgarum carbidum nostrorum praestandam.Per inspectiones strictissimae qualitates, in unaquaque massa congruenter qualitatem efficere possumus.

Kedel Carbide Rod Types

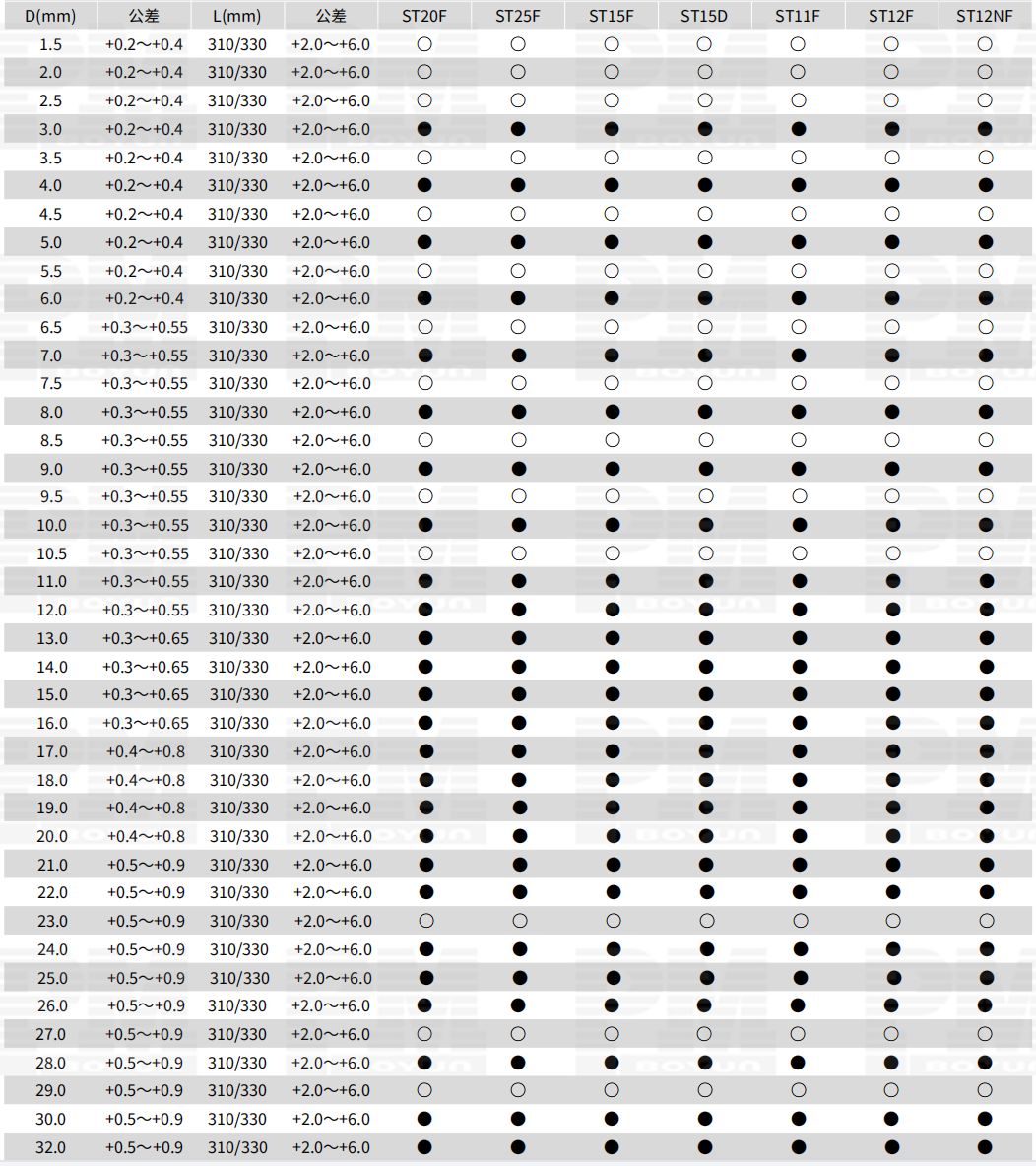

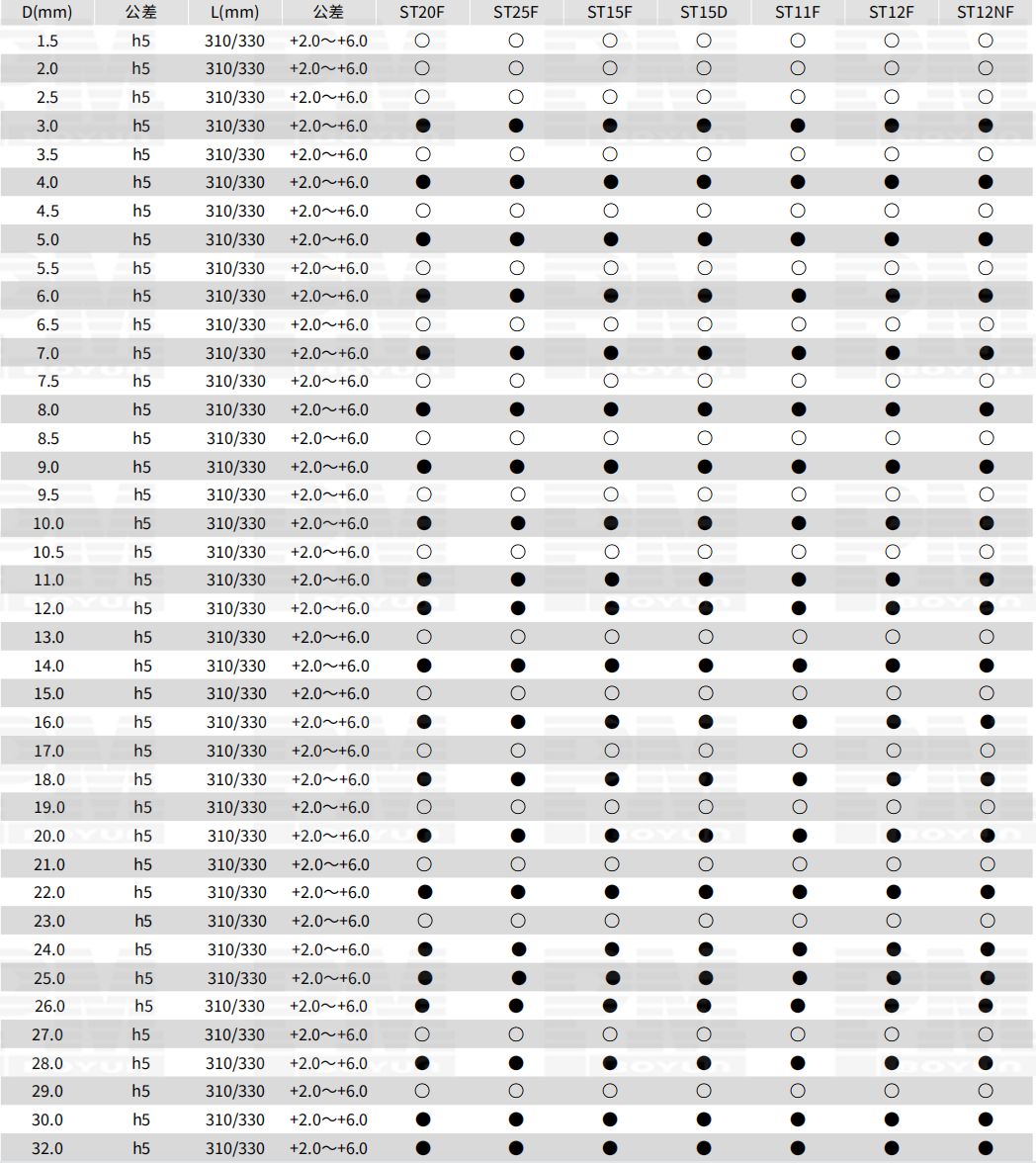

1. solidi Carbide dii in Metrics

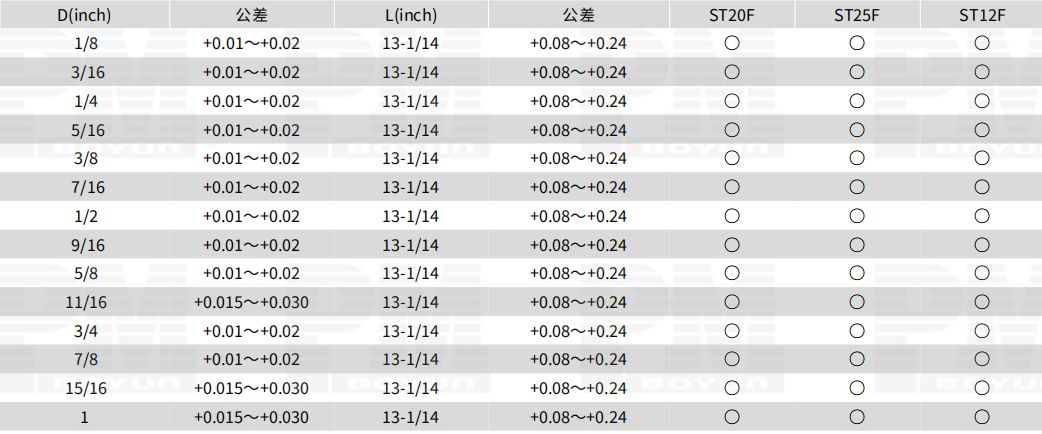

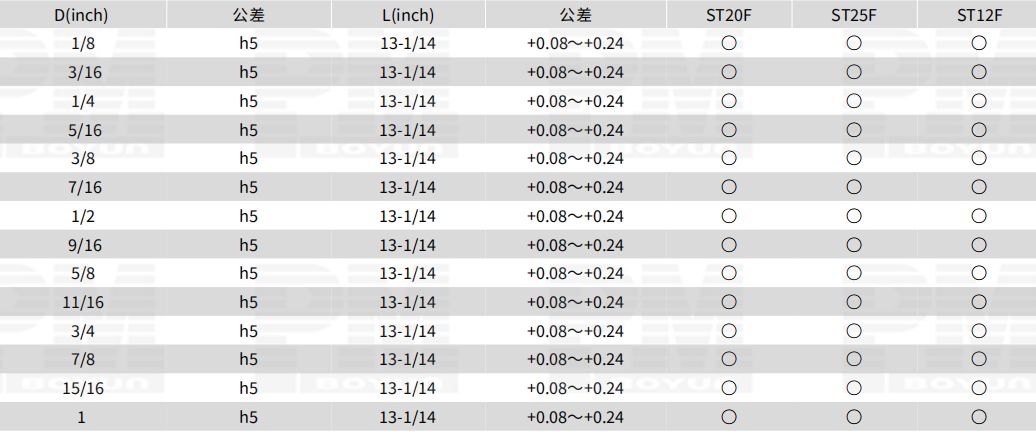

2. Firmus Carbide dii in Uncias

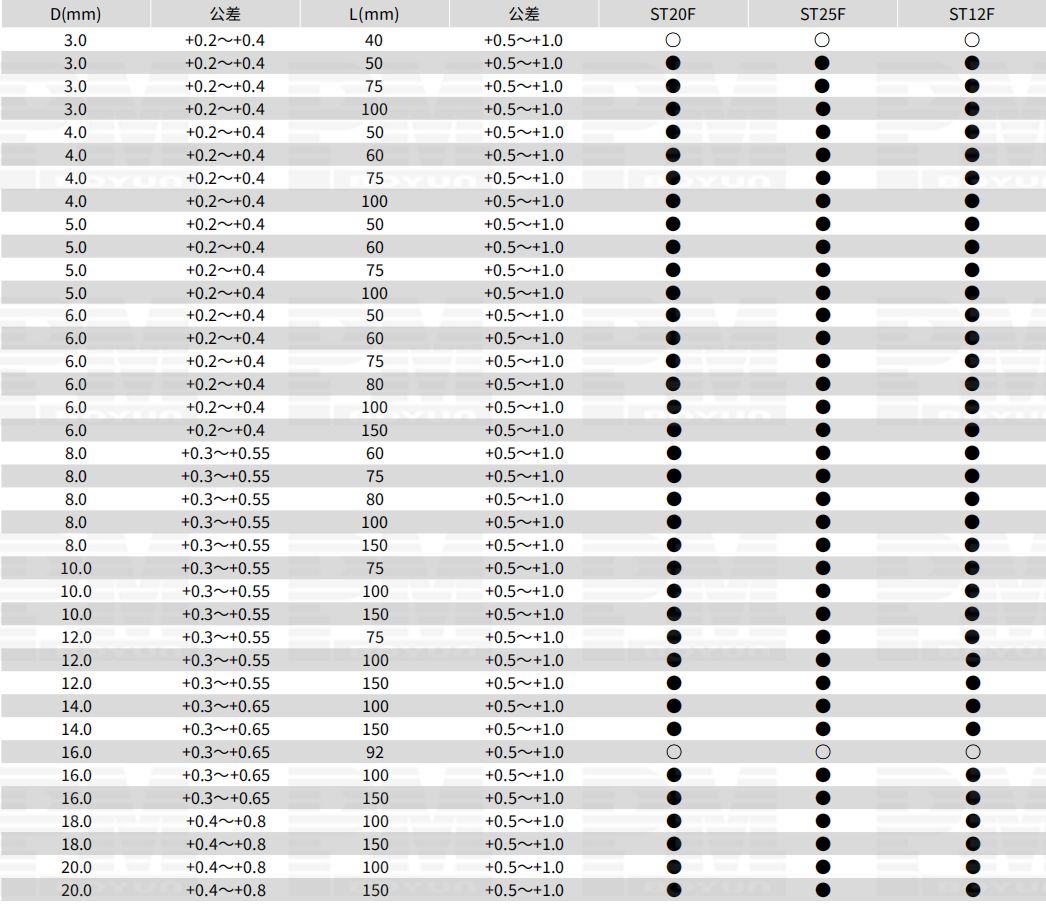

3. EXERCITATIO Blanks (Chamfered)

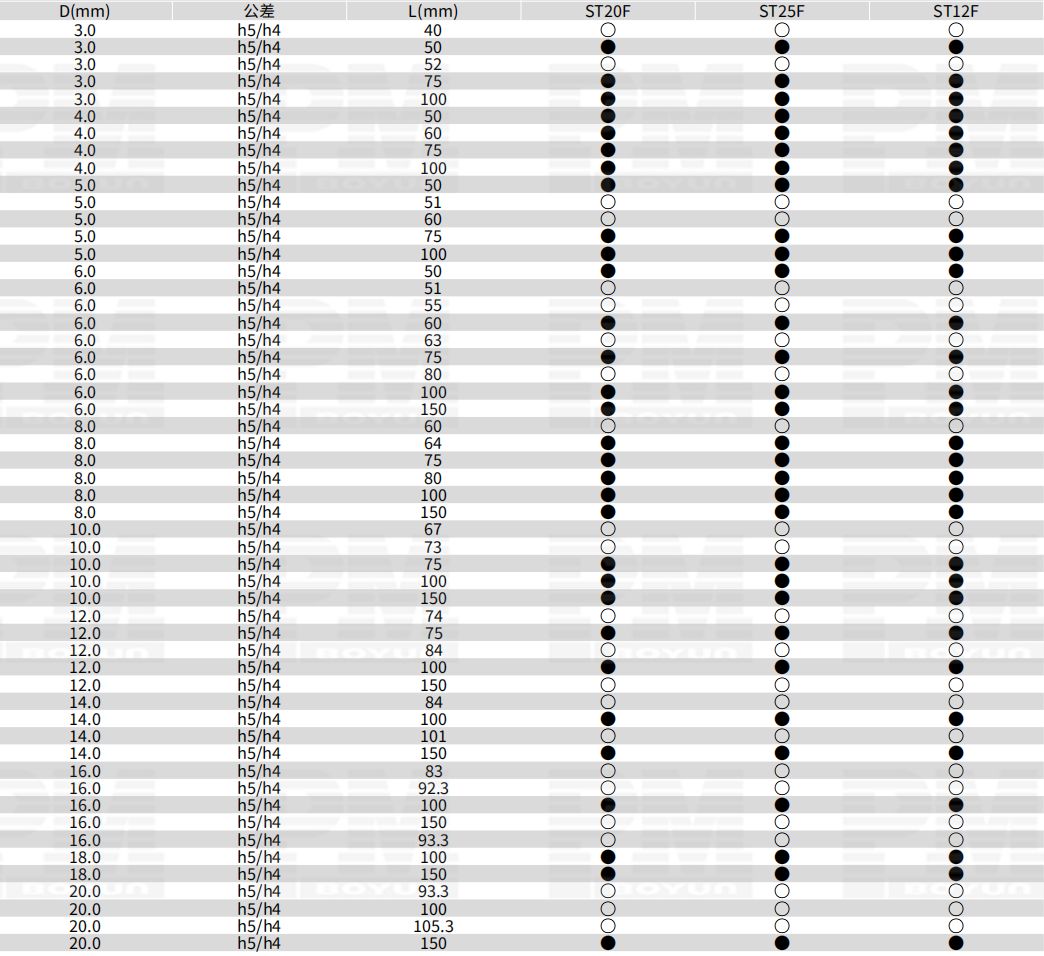

4. finis molendinum Blanks (Chamfered)

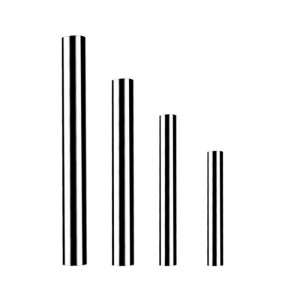

5. Carbide dii recta Centralis Coolant Hole

6. Carbide virgae duae rectae Coolant Holes

Carbide Rod Characteres

1. per altum qualis tungsten carbide superfine pulveris

2. Subtilitas instrumenti cum 10MPa HIP-Sinter camini normatum fabricandi.

3. Maximum duritiem et excelsum fortitudinem

4. Praecipua commoda: Rubra durities, obsistens gerunt, altae elasticitas modulus, TRS, stabilitas chemica, impulsus obsistens, coëfficiens dilatatio humilis, calor conductio et conductio electrici idem cum ferro.

5. Praecipua technologia: pressio alta siteratio caliditatis vacui.Porositatem reducere, soliditatem et proprietatem mechanicam reducere.Varii gradus, genera et magnitudines.

6. Diversus gradus ad referat.

Communia Amplitudo

Gradus List

| Gradus Introductio ad Carbide Rods | |||||||

| Gradus | Co% | WC frumenti magnitudine | HRA | HV | Densitas (g/cm* | Tendens robur MPa) | Fractura durities(MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Fine | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Ad ulteriores notitias (MOQ, pretio, traditione) vel si operas customizationes indiges, prolationem postulas.